The BAMTEC® – Advantages

Time pressure, budget pressure, margin pressure and shortage of skilled workers and ever increasing quality requirements.

Reinforcement Technology. It is the most economical and fastest reinforcement solution for slabs, slabs on ground or walls.

These are the daily challenges for the construction industry.

For the reinforcing steel sector, the solution is BAMTEC®

The 4 main advantages at a glance

Time is

money

Time is

money

With BAMTEC® you save time, a lot of time.

Material

saving

Material

saving

With BAMTEC® material can be saved. This saves costs and resources.

Quality

Quality

Thanks to the fully automatic and continuously data controlled BAMTEC® planning and production you receive customized reinforcement in highest quality.

Added

value

Added

value

BAMTEC® creates added value from which everyone benefits.

With BAMTEC® you save time, a lot of time.

With BAMTEC® material can be saved. This saves costs and resources.

Thanks to the fully automatic and continuously data controlled BAMTEC® planning and production you receive customized reinforcement in highest quality.

BAMTEC® creates added value from which everyone benefits.

The BAMTEC® – Installation benefit

The installation of BAMTEC® carpets is very easy!

BAMTEC® carpets can reach an area of several hundred m2 when rolled out. This massively reduces the number of reinforcement elements to be installed…

A possible shortening of the shell construction time leads to considerable cost savings.

„Installing instead of tying“ – the future lies in prefabrication

BAMTEC® is the tailor-made and prefabricated solution for surface reinforcement, in use since 1998. The advantages are obvious. The trend is clearly towards prefabrication – also in the reinforcing steel sector. BAMTEC® together with e.g. bent standard meshes as side reinforcement or prefabricated and welded reinforcement modules will massively increase the productivity during the installation on the construction site in the future.

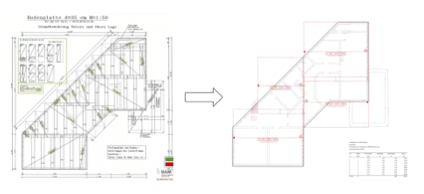

Quality control made easy

Due to the fully automatic, continuously data-controlled production, custom-made BAMTEC® carpets are delivered to the construction site. The positioning of each BAMTEC® carpet is indicated on the installation plan. This guarantees exact positioning accuracy and high installation quality. Much fewer reinforcement elements have to be installed. Quality control is reduced to a minimum.

Material savings

With the optimized BAMTEC® design, based on static calculation and a FEM software (Finite Element Method) it is possible to save 20-40 % steel. Due to the fully automatic and continuous data controlled production the highest quality is guaranteed.

The BAMTEC®-plant processes bars up to 20 mm from coil. Furthermore BAMTEC® is highly flexible. Each BAMTEC®-carpet can contain bars of different diameters and lengths – there is no waste and therefore saves costs.

Compared to meshes, BAMTEC® can always save 10-20 % material. The area of rolled out BAMTEC® carpets can be several 100 m2. This leads to much less overlapping and saves material.

References

Tissot-Arena – Biel, Switzerland

Nola II – Italy

Vadian – St. Gallen, Switzerland

Airport Budapest – Hungary

Klinikum Kempten – Kempten – Germany

Uetliberg Tunnel – Switzerland

Orkdalsvegen Tunnel – Norway

Highway A50 – Holland

Jansen – Oberriet, Switzerland

Brandenburger Urstromquelle – Germany

Winnersh – U.K

RWE-Tower – Dortmund, Germany

Home of FIFA – Zurich, Switzerland

Primavera Oy – Germany

Interested in BAMTEC®?

Contact us – we will be glad to help you immediately.